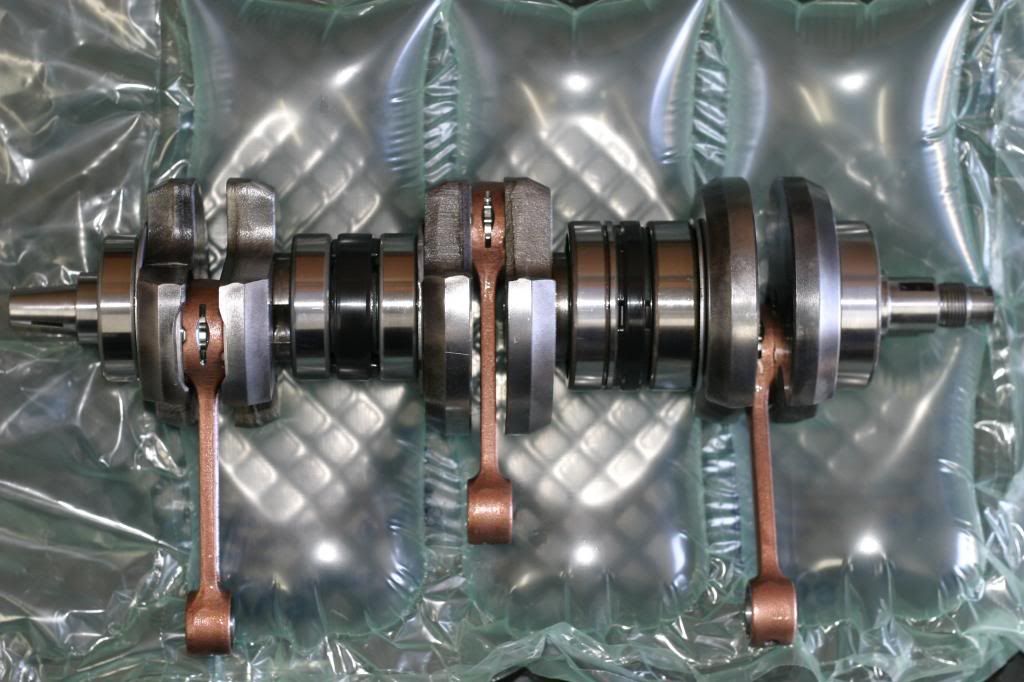

This H2 crank was finished today. I cant get it any straighter than it is. rebuilt with all new parts and ready for a new lifetime of service for one of our board members H2 he is currently building.

Here is an example of some of the quality parts I offer on my Kawasaki Triple crankshaft rebuilds.

I prefer to use good quality parts as I think its money well spent to insure not having to redue

your crank with seals or bearings that might cause problems before its time. I have lab seals that made

in the US as well as the reliable K&S rubber seals . These are the same ones we all use for outer seals.

Bearings come in all grades and quality. Some rods can be reused after a complete inspection of the

important surfaces or replace the rods for the long haul. I will do it your way and budget. Some folks

want to premix some dont. Some want all non rotating bearings . I can help with advise on shipping

methods . I do have some outright cranks and misc parts if yours is needings parts. I have many

great running engines out there running and racing with cranks Ive rebuilt. I have a reasonable turnaround

but only do them as if I was going to use the crank in one of my engines. I do help in coaching or advise on

assembly of the engine as well. This is where the whole thing starts as far as if you engine is going to run correct,

run smooth and make you top end last.

Thanks Porschedave