Gathering my numbers to see where I am at with the top end. We'll call this the start!! I am really glad to be amongst you all again. I really missed this forum.

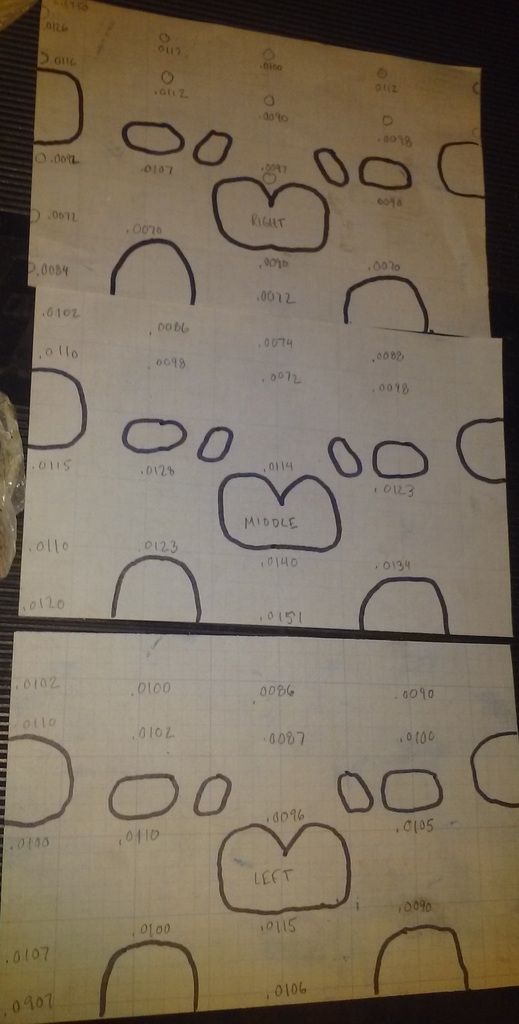

I was using a 3-point Browne & Sharpe--saweeet gage btw. Anyways I wanted a way to record my numbers, so I made up some worksheets, and used some blue dye to transfer the general location of the ports to my worksheet and boom. Now I have a way to see taper and diameters top to bottom of each jug.

I did 5 elevations, and took 4 measurements pretty close to each quad point (12, 3, 6, and 9 oclock).

Here's a collage.

The number sheets are below for Right, Middle, and Left. To each one of these measurements, add 2.375".

I left my spec sheets at work and will have to check the ranges, and not sure what the possibilities are for boring if I need to. Getting late so I will push through the numbers tomorrow, get some max mins, avgs etc.

EDIT: just found the specs on the resource site....2.3681" Service Limit.

The pistons appear to be factory, cast, and are marked 0.50 on top. The skirts at the base measure approximately 60.44mm. So where do I go from here?