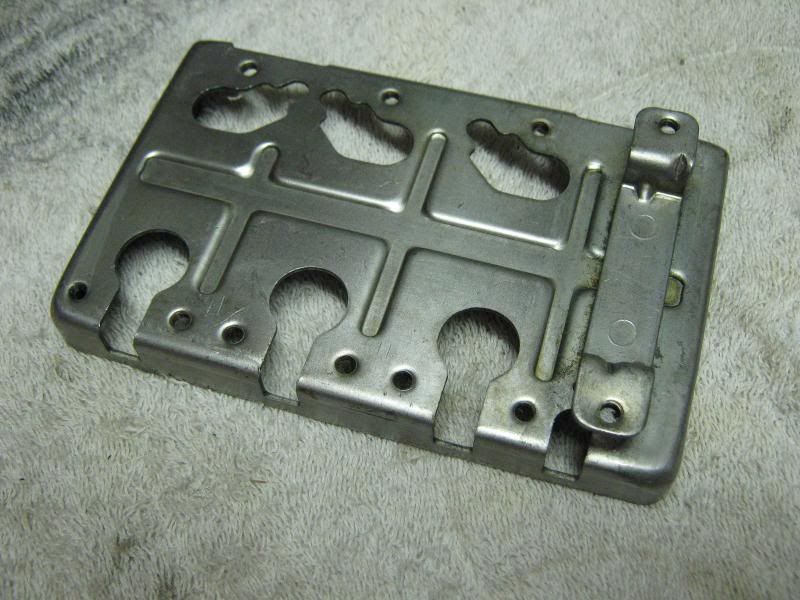

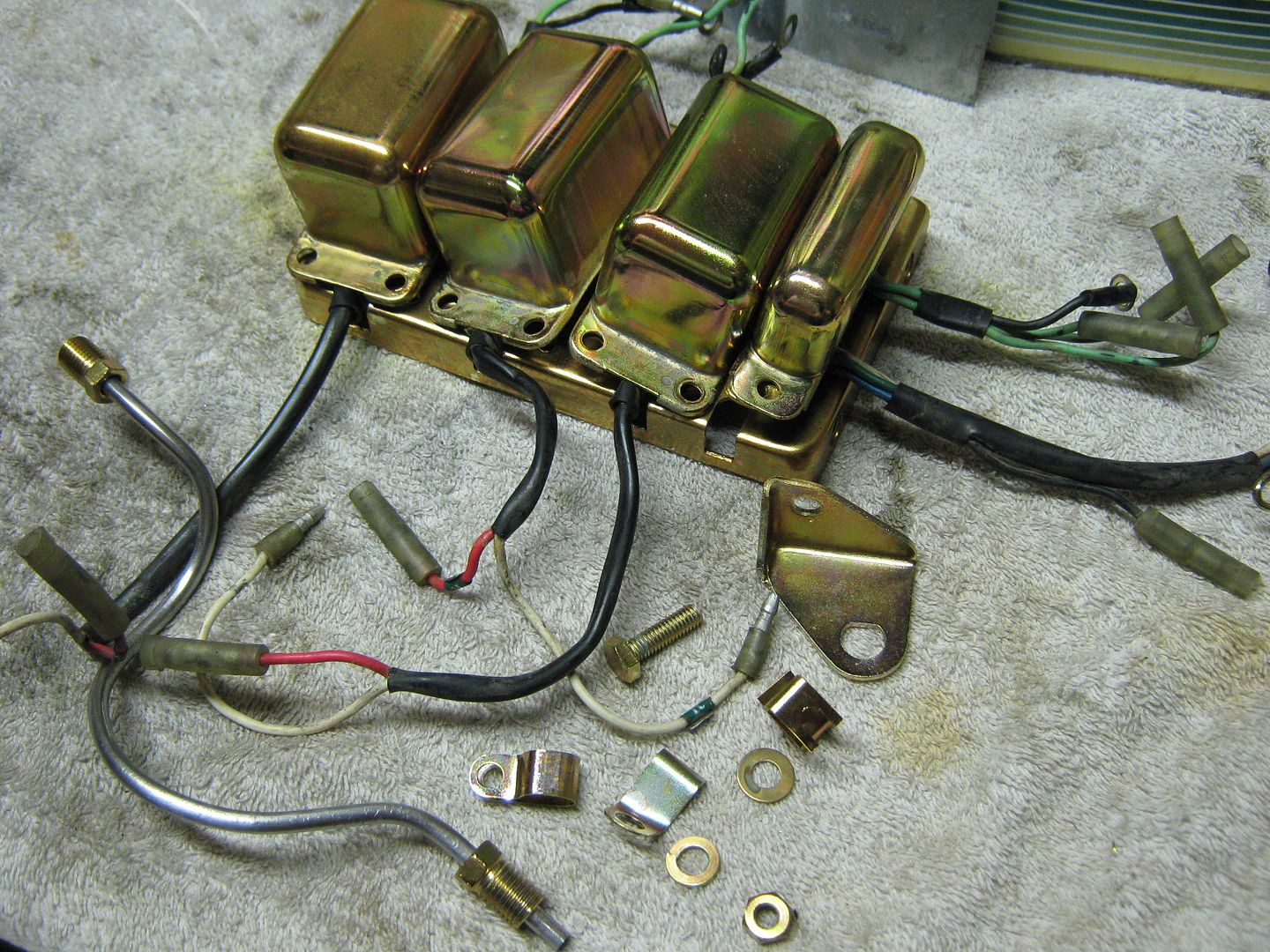

I used the Caswell plating kit for the fasteners on the B8 I fixed up and it worked great so I bought the gold anodizing solution to go with the Copy-Cad kit. I needed to spruce up the CDI's on the H2 I am putting together. I sanded them down with 400 and then 600 and then buffed with 0000 steel wool. I found with the plating kit that the smoother the surface you plate the shinier it turns out. I dunked the CDI's for 60 seconds in the anodizing bath after I had them in the zinc plate bath for about 10 minutes. I use a little extra brightener in each batch, about twice what it calls for, just because I get better results this way. I think the gold anodize turned out okay. The cleaning solution is between 190 and 200 degrees and I knew the CDI's couldn't take that kind of heat so I called Caswell and their tech guy said it's fine to clean with 409 or simple green or something else before you plate. I used acetone to clean and then did the normal zinc with brightener plating cycle. I submerged the CDI completely in the zinc and the anodize baths(I figured they are sealed and it would be fine, plus I saw no bubbles coming up from them during the plating and the zinc is only 120 degrees for 10 minutes and the anodize bath is room temperature. Now I just hope they work because I didn't test them before I made them look Purdy again.